ARTIFICIAL INTELLIGENCE: THE FUTURE OF LITHIUM BATTERIES, VINCENZO’S THESIS

In this exclusive interview, we meet Vincenzo, a young and talented computer engineering graduate student, who chose Archimede Energia as the stage for his master’s thesis. With an innate passion for artificial intelligence and a growing interest in the lithium battery sector, Vincenzo had the opportunity to work on an ambitious project: the development of fault detection software. This innovative tool promises to revolutionize the production and maintenance of lithium-ion batteries by enhancing efficiency and safety. Let’s explore his journey, the challenges he faced, and the future prospects of this promising young engineer.

BACKGROUND

Hi Vincenzo, could you tell us a little about yourself? What drove you to choose such an innovative project for your thesis?

Hi, I’m Vincenzo. I’m 25 years old and currently a master’s student in Computer Engineering at the University of Parma. In 2023, Ing. Manuele Conti from Archimede Energia introduced me to this thesis project, which perfectly aligned with my academic path focused on artificial intelligence. The innovative potential of this technology was evident right from the start.

The thesis represented an extraordinary opportunity to practically apply artificial intelligence in an industrial context like Archimede Energia and to gain significant formative experience.

Why did you decide to focus on the lithium battery sector and Archimede Energia’s production? What’s the most fascinating aspect of this field?

Initially, I was working with Archimede Energia through Tecnogen, a company that produces generators, helping them develop a web portal for managing their batteries via IoT systems. So, we could say I seized a series of opportunities, aiming to participate in projects that aligned with my academic path. The most fascinating aspect is that the lithium-ion battery sector is constantly evolving, presenting new challenges for those eager to experiment and step up.

What was your first impression when you started working on the project? Did you immediately realize the potential of the fault detection software?

I thought it was an interesting project but with many inherent difficulties. Although my thesis officially started in March 2024, I began researching nearly a year earlier because even reading an article quickly reveals the complexity of this task. At the same time, it’s fair to say that the toughest challenges hold the most potential, and fault detection software, like machine learning in general, offers significant prospects.

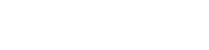

THE THESIS PROJECT AND FAULT DETECTION SOFTWARE

Can you briefly explain what the fault detection software you’re introducing entails? How does it work?

Initially, I developed various diagnostic algorithms to compare the performance of different methodologies. These can be divided into two categories:

- Signal-based: These include methods using techniques like filtering, transformation, compression, and feature extraction to analyze data.

- Data-driven: These rely on patterns, statistics, and machine learning models to analyze data and make data-driven decisions.

I then decided to integrate these diagnostics through a weighted voting system, creating a hybrid system that performs better than individual algorithms.

What are the main benefits of using a fault detection system in lithium battery production?

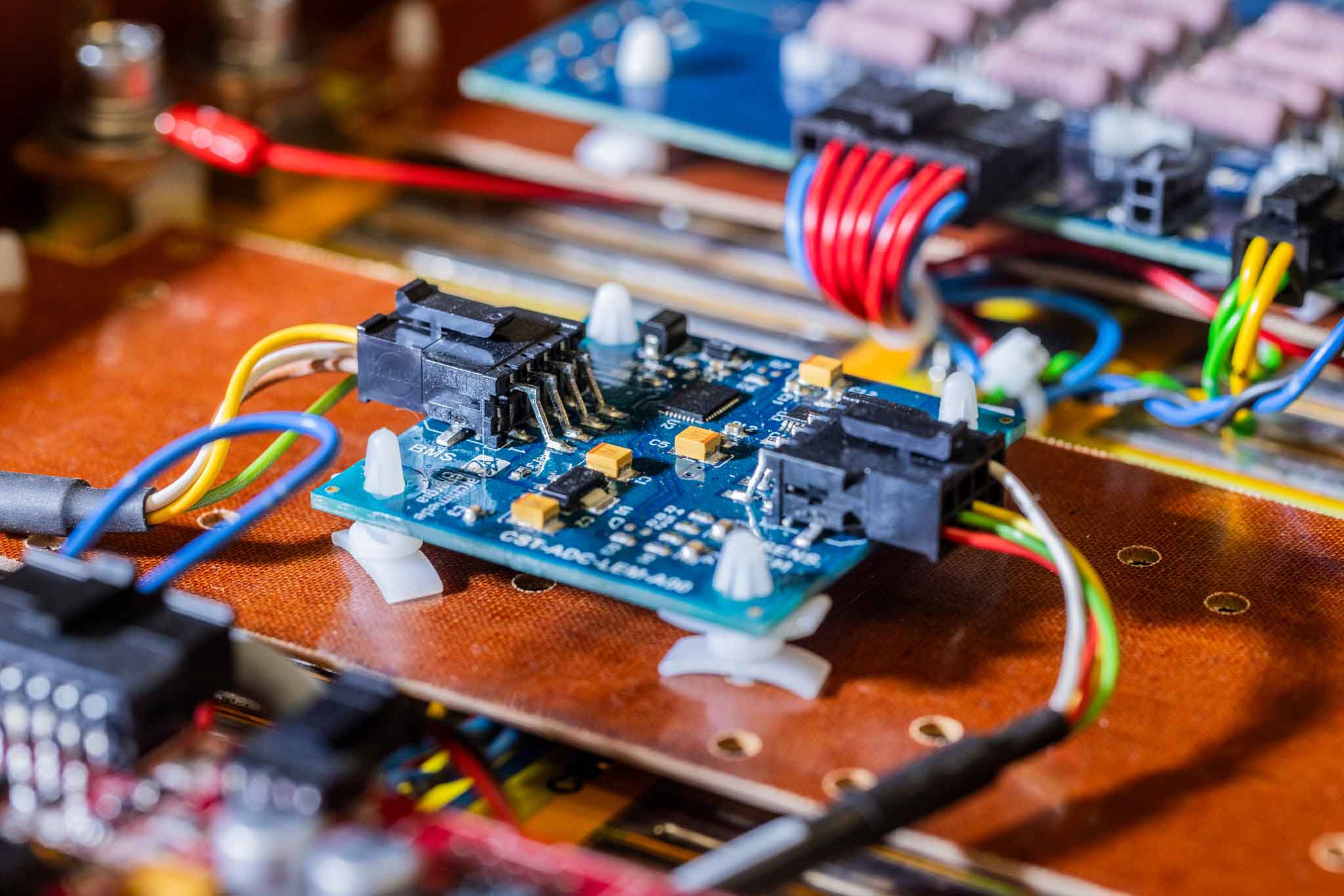

A fault detection system like the one implemented is an automation tool enabling real-time monitoring, saving work hours since technicians in any company are valuable and limited resources.

Did you encounter any technical challenges while developing the software? How did you overcome them?

Signal-based algorithms require rule implementation, which becomes more complex the more intricate the system being represented, as with lithium-ion batteries. Data-driven algorithms, on the other hand, need high-quality data and the ability to train and adapt the model to the challenges faced. While the latter is the developer’s responsibility, the former results from good procedures and a long-term vision.

How can fault detection software impact the efficiency and safety of battery production?

In various lab tests, the fault detection algorithm identified anomalies that aligned with Archimede Energia’s standards months before customer reports. As it stands, the developed algorithm would elevate Archimede Energia’s customer service and battery monitoring, improving assistance efficiency and customer safety.

How does this influence the overall quality of the final product?

Battery defects suffer from an unfortunate cascading effect, as one issue can lead to the emergence or exacerbation of others. Detecting and resolving an issue promptly reduces the likelihood of subsequent problems, containing costs and improving product quality. The fault detection algorithm identifies cell damage and inconsistencies in the battery pack, allowing for quicker problem resolution compared to the current state and mitigating the aforementioned cascading effect.

INNOVATION AND SUSTAINABILITY

How do you think this software could influence the future of battery production? Do you see broader applications?

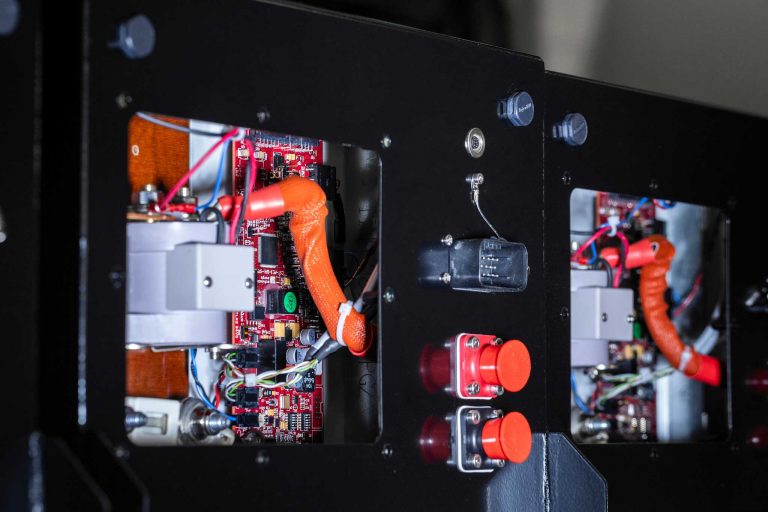

Artificial intelligence is not an all-powerful oracle; currently, the term mainly refers to weak AI, systems designed to perform specific tasks. Therefore, computer engineers must adapt each model to the problem at hand, enabling endless potential applications. Limiting to the field of lithium-ion batteries, these same models could estimate the state of charge (SOC), state of health (SOH), or suggest input current values to extend battery life (RUL).

Sustainability is a hot topic, especially when it comes to lithium batteries. How can fault detection contribute to making production more sustainable?

A battery’s job is defined in kWh, the amount of kW required in an hour for a given use. When a battery loses about 30% of its capacity, it’s considered unfit for its current application. At this point, two paths emerge:

Assess its remaining kWh and assign it a task better suited to its current capabilities, giving it a second life.

Since batteries tend to align their deliverable kWh to the cell with the lowest capacity in the pack, prolong its useful life by keeping all cells above an acceptable threshold for its current use.

The fault detection algorithm applies to the second point, as it extends the life of lithium-ion batteries and minimizes the time between actual failure and customer service intervention, reducing downtime for battery usage (and consequently costs for the customer).

THE FUTURE

What advice would you give to a student aiming to pursue a thesis or career in industrial automation or applied artificial intelligence like you?

University offers a lot of knowledge but is only a starting point. Some say the first working years can be seen as a sort of specialization. I managed to get ahead by experiencing this simultaneously with my master’s degree. My first advice is to talk to professors, as they often have contacts in various companies. The second is to give it your all, step up, and seize all available opportunities because effort and dedication always pay off. Sooner or later, opportunities will come.

Can you give us a sneak peek into your next career steps or the project you’re developing?

Archimede Energia is part of a holding that purchases batteries from them. This means creating an R&D group for this project would benefit not only Archimede Energia but anyone tied to their products. I can’t predict how the project will evolve, but given the results achieved and the positive feedback from industry experts, professors, and Ph.D. candidates, it would be a waste to abandon it without giving it due recognition.

FINAL THOUGHTS

We at Archimede Energia thank Vincenzo for his invaluable contribution and take this opportunity to support all young people who, like him, face today’s challenges with determination and passion. We firmly believe that, with ambition and confidence in one’s abilities, important goals can be achieved.

If you want more information about our projects or collaborations, don’t hesitate to contact us: we’re always ready to engage and take on new challenges.