Energy optimization with modular Lithium Batteries: flexible and scalable solutions for Electrical Applications

Many applications that use electric traction systems or lithium energy storage require connecting more than one battery to the system. This need typically arises to achieve the following goals:

- Increase in DC Bus Voltage: By connecting multiple batteries in series, the total voltage of the storage system can be increased, allowing greater efficiency and flexibility in energy use.

- Extended Range: By connecting batteries in parallel, the overall capacity of the system increases, enabling more energy storage and extended application range.

- Reliability and Redundancy: A battery cluster provides greater reliability through redundancy, ensuring that the failure or malfunction of a single battery does not compromise the entire system.

- Weight and Space Distribution: Distributing batteries within a cluster optimizes weight and space management in the vehicle or system.

- Scalability: Using the same battery model, the system’s range can be modulated for different energy applications, ensuring greater flexibility.

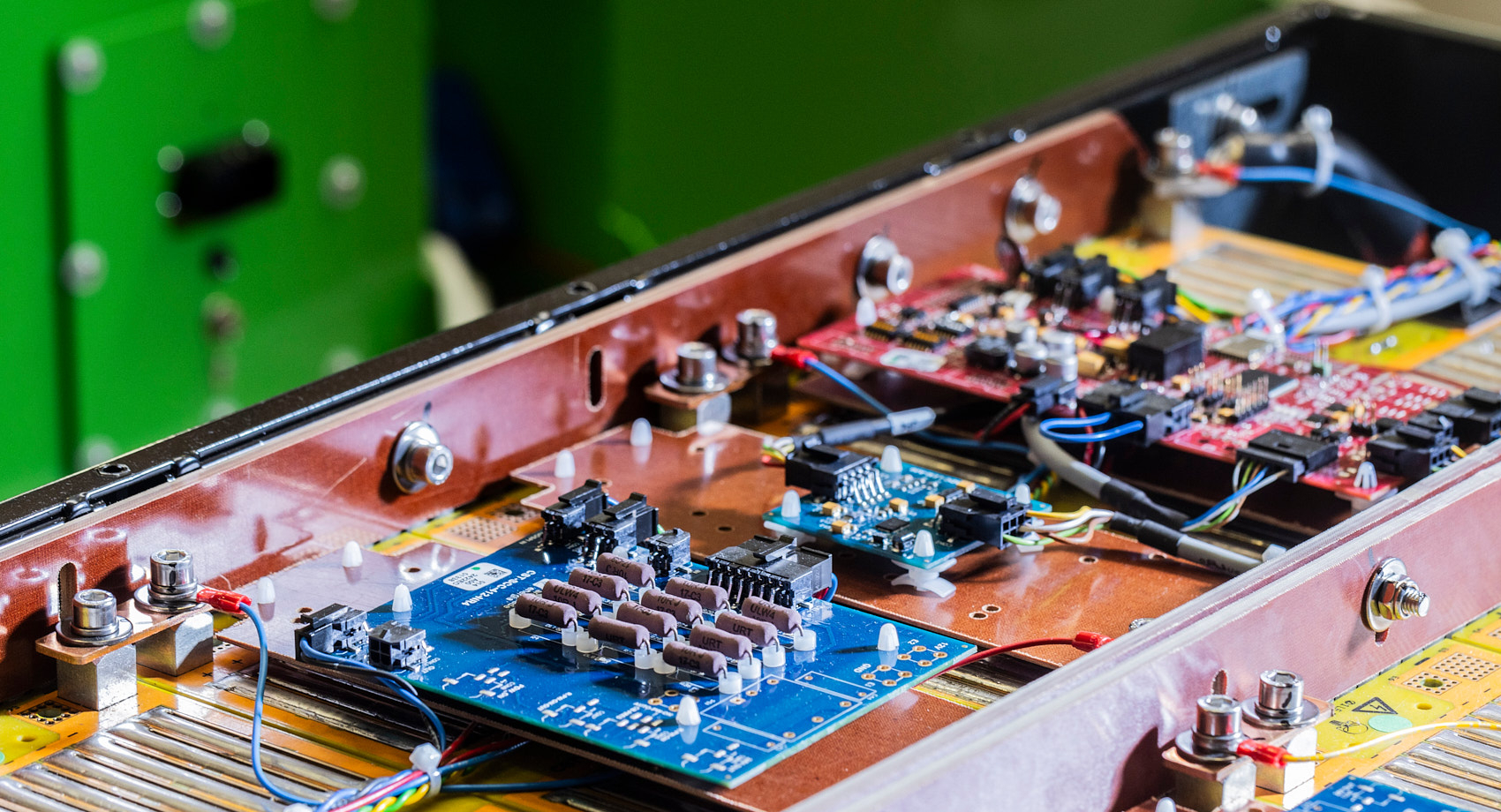

THE MODULAR LITHIUM BATTERY SYSTEM

The lithium battery cluster from Archimede Energia is a modular system composed of multiple interconnected elements. This software architecture enables monitoring and managing module information, including voltage, current, and temperature. The individual batteries within the cluster system communicate via the CANbus protocol and are able to operate as a single storage system following well-defined operational logic.

Depending on the system requirements, different cluster topologies can be assembled. The most commonly used include:

- Series Cluster – Batteries are connected in series, maintaining the final system capacity while increasing the DC bus voltage.

- Parallel Cluster – Batteries are connected in parallel, keeping the DC bus voltage constant and increasing system capacity.

- Parallel Series Cluster – Combines several strings of batteries connected in series, increasing both system capacity and DC bus voltage.

These configurations effectively meet various system needs where a single battery is insufficient.

INTERFACE AND COMMUNICATION

An electronic interface communicates all system information via CANbus, enabling the control of CANbus chargers like Zivan, DeltaQ, and Atib, as well as common inverters like Victron and Studer. Additionally, system communication allows the user to operate the cluster as if it were a single battery, simplifying the transition from a single battery to a modular system without the need for a new implementation.

PRACTICAL APPLICATIONS

A concrete example of this architecture’s use is the Enerpack systems by Tecnogen. These BESS systems are compatible with both existing and new solar installations. The modular design provides a storage capacity ranging from 30 to 720 kilowatt-hours, enabling backup power for the entire system. Battery usage and consumption can be monitored through a mobile application or web portal. Designed to integrate with an existing external generator or to function as a standalone system without a solar setup, the BESS system is suitable for small- to medium-sized solutions, utilizing a cluster of multiple PJO-400-74-TDA units to create high-performance energy solutions.

For more information, refer to the product sheet for Tecnogen: click here.