With the rapid rise of electric mobility and the increasing use of lithium batteries in industrial and stationary applications, thermal management has become one of the most critical challenges for ensuring performance, safety, and long-term durability. Among the most promising and innovative solutions is Immersion Cooling.

In recent years, immersion cooling has emerged as a groundbreaking thermal management solution for batteries used in electric vehicles (EVs). With the electric vehicle market projected to grow by 36% annually over the next decade (according to the IEA), optimizing battery performance has become essential.

In this article, we explore what immersion cooling is, how it works, and why it represents a turning point for Archimede Energia, a manufacturer specialized in high-efficiency lithium batteries.

What is immersion cooling?

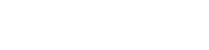

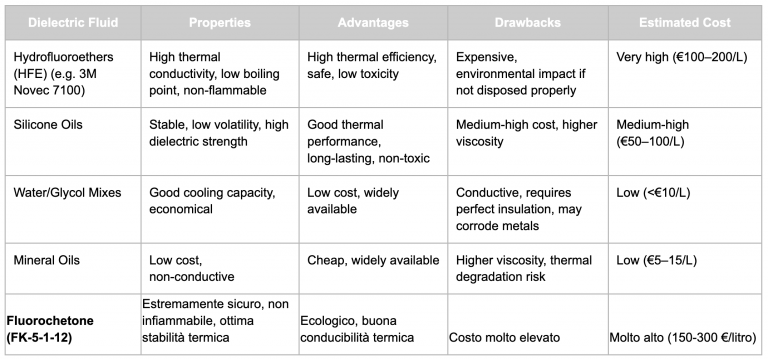

Immersion cooling is an advanced cooling technology in which battery cells are submerged in a dielectric (non-conductive) fluid that directly absorbs the heat generated during operation. Unlike traditional air- or liquid-based systems with secondary circuits, this approach enables much more efficient and uniform heat dissipation.

Originally developed for power electronics—particularly in data centers—this technology is now proving strategically valuable for lithium batteries in both automotive and stationary applications, due to its ability to meet demanding performance and longevity requirements.

How does immersion cooling work?

The concept is “simple”: by fully submerging the battery module in a dielectric fluid, direct contact is established between the heat source and the cooling medium. Heat is uniformly absorbed and transferred to a dissipation system (usually a heat exchanger), keeping the cells within their optimal temperature range.

There are different system configurations, including:

- Single-phase immersion cooling: the fluid remains in liquid form and is circulated in a closed loop.

- Two-phase immersion cooling: the fluid evaporates as it absorbs heat and then condenses, offering even higher thermal performance.

What are the advantages of immersion cooling for lithium batteries?

Implementing immersion cooling brings several measurable benefits:

- Uniform and stable cooling

Eliminates hot spots and ensures consistent temperature distribution, allowing cells to operate under optimal conditions. - Enhanced safety

Reduces the risk of overheating, short circuits, and thermal runaway, improving system stability. - Energy efficiency

Lowers the energy consumption required for active cooling, improving overall system efficiency. - Compact design

By removing fans, heat exchangers, and complex piping, it enables lighter and more compact battery packs. - Longer battery lifespan

Lower and more stable temperatures reduce thermal stress on the cells, extending their life cycle.

Key types of immersion cooling systems for batteries

In lithium battery applications, various configurations are used, each with distinct characteristics that influence their suitability for different use cases:

- Pumped Liquid

Dielectric fluid is pumped through battery cells to absorb heat, then circulated through a heat exchanger.

Pros: High thermal efficiency, ideal for large systems.

Cons: Requires mechanical components like pumps and piping, increasing system complexity and cost. - Spray Cooling

Dielectric fluid is sprayed directly onto battery cells, where it evaporates and is later condensed and recycled.

Pros: High cooling efficiency, minimizes local overheating.

Cons: More complex to implement, requires vapor management. - Pool Boiling / Vapor Chamber

Cells are immersed in a fluid that boils on contact with hot surfaces, transferring heat via evaporation and condensation.

Pros: Excellent thermal efficiency, uniform heat distribution.

Cons: Requires precise fluid and temperature management. - Gap Filter

Fluid is circulated through narrow channels between battery cells, absorbing and removing heat.

Pros: Compact design, suitable for space-limited systems.

Cons: Requires careful fluid dynamics design to ensure uniform flow. - Static Bath

Cells are immersed in a non-circulating fluid, which absorbs heat via conduction and natural convection.

Pros: Simple design, low maintenance.

Cons: Lower thermal efficiency than dynamic systems. - Pumped Two-Phase

Dielectric fluid is pumped through cells, changing from liquid to vapor to absorb heat, then condensing and recycling.

Pros: High thermal efficiency, ideal for high-density systems.

Cons: Higher cost and design complexity.

Depending on the application—electric traction, industrial storage, UPS—one can select the most suitable system by balancing efficiency, space, and cost.

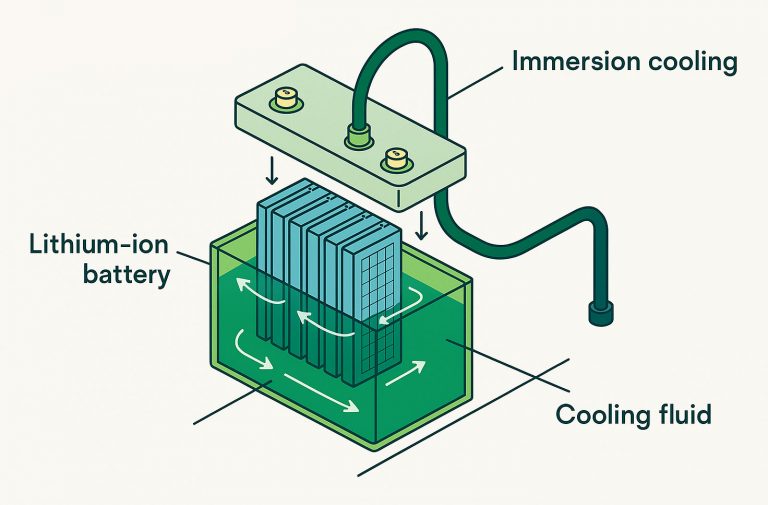

What fluids are used in immersion cooling?

The choice of dielectric fluid is crucial to system performance. Common options include:

Hydrofluoroethers (HFE), Silicone oils, Water/glycol mixtures, Mineral oils and Fluoroketones (e.g., FK-5-1-12).

At Archimede Energia, we choose high-performance, eco-friendly dielectric fluids that are compatible with our cell architectures.

Where is immersion cooling useful for lithium batteries?

This technology is rapidly gaining adoption in sectors such as:

- Electric vehicles (EVs) – to ensure range, safety, and high performance over long cycles

- Industrial and residential energy storage – where thermal stability is critical

- UPS and backup systems – to maximize reliability in critical situations

- Naval and railway applications – where compactness and safety are essential

Is immersion cooling safe?

Yes. The fluids used are:

- Electrically non-conductive

- Non-flammable

Long-lasting and chemically stable - Safe for operators

However, it’s essential to work with a partner with advanced expertise in thermal design, materials chemistry, and battery systems engineering.

What are the challenges of immersion cooling?

Key challenges include:

- Fluid cost – still relatively high, especially for two-phase systems

- Material compatibility – not all battery components are suitable for immersion

- Fluid maintenance – requires quality monitoring and eventual replacement

- Advanced system design – requires specific know-how in fluid dynamics and thermal engineering

The future of immersion cooling for lithium batteries

According to market forecasts, the use of immersion cooling in energy storage systems is expected to grow at over 22% annually through 2030. While fluid cost and system complexity remain hurdles, this technology represents the future of thermal management in EV batteries.

At Archimede Energia, we believe immersion cooling should become a design standard for future lithium systems—safer, longer-lasting, and higher-performing.

Immersion Cooling is revolutionizing how we manage heat in battery systems. With benefits ranging from safety to sustainability, this technology is set to become a key benchmark for anyone designing advanced solutions for energy efficiency.

Want to explore how to implement Immersion Cooling in your lithium battery system?

Contact us—our technical team is ready to help you find the ideal solution for your project.